Measuring system for Plastic bottle & Preform MTY-7000

|

Measuring time: 4sec or less

|

|---|

Characteristics

- Subjects for measuring

- Plastic bottle , Preform

200ml~2000ml - Measurement Items

(details for measurement positions) -

- Mouth inside diameter (2points)

- Mouth outside diameter

- Outside diameter of thread

- Diameter across thread root

- Body outside diameter

- Bead outside diameter

- Bead height

- Neck support height

* The MTY-7000 equipped with specially designed linear gauge measuring heads measures the pet bottle & preform bottle of PCO

Feature

- Measuring time is as short as 4 seconds in any one direction

- The MTY-7000 offers an accuracy of 4μm or less in terms of σ when repeated measuring the master gauge 10 times at a fixed point

- The measured values are digital displayed.

- GO / NG judgement result is indicated by the lamps. (Tolerances can be set as desired)

GO:The green lamp lights

+NG: The red lamp lights

-NG: The amber lamp lights - The measurement data can be output via the RS-232C interface.

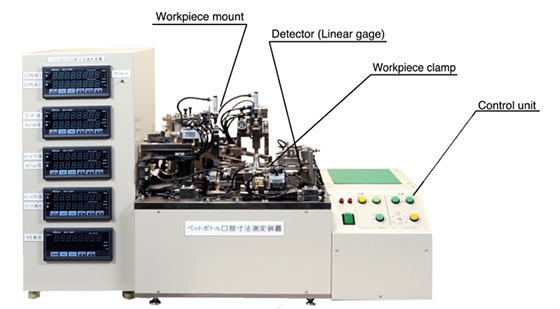

- The MTY-7000 is a semi-automatic measuring system that allows easy operation and simplified measurement.

- With a small CCD camerea, thecondition of workpiece (pet bottle preform) setting can be checked.(12-inch monitor is supplied together)

- The MTY-7000 is designed with operational safety in mind.

- The workpiece (pet bottle & prefoem) can be measured from two directions (from the angles at 0°and 90°). (Automatic 90°-workpiece-rotation function is optional)

Spec

| Item | Content |

|---|---|

| Measuring head |

|

| Display |

|

| Measurement accuracy |

|

| Workpiece loading | Manual loading Automatic loading function is optional |

| Measurement procedure |

|

| Cycle time | Within 4 sec from the moment the switch is pressed ON to the measured values is displayed |

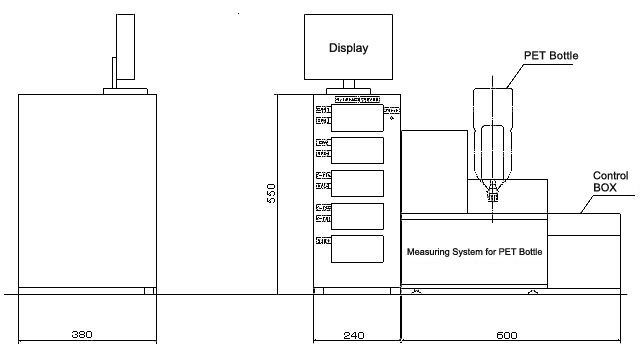

| Dimensions | Main unit: W500 x H610 x D340mm Display for measured vakues: W240 x H580 x D380mm |

| Line voltage | Selectable 100V±10% 50/60Hz 300VA |

| Compressed air source | 0.4 - 0.5MPa (approx 4.1 to 5.2kgf/c㎡) |

| Mass | 50kg or less (standard) |

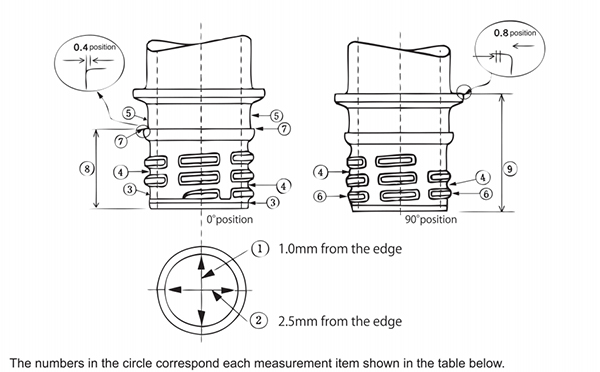

An example of objects to be measured and measuring points

- Workpiece:

- Pet Bottle & Preform

- Applicable workpiece capacity:

- 200ml, 500ml, 600ml, 900ml, 1000ml, 1500ml, and 2000ml.

- Measurement positions/points:

- (the master gauge is shown as an example in the figure below)

- Detailed measurement positions:

- Shown below

- Measurement points

- Described in the table below.

- Remarks:

- The following measurement positions/points are just for example and measured when our demonstrative machine is used.

Upon your request, the machine based on other specificstions can be supplied as far as its production is within our capacity.

| Measurement item / position / number | Initial setting of measurement position (at 0° position) | Master gauge nominal size (mm) | Master gauge measured value |

|---|---|---|---|

| 1. Mouth inside diameter | Position 1.0mm away from top | φ20.60 | ±0.05 |

| 2. Mouth inside diameter | Position 1.0mm away from top | φ20.60 | ±0.05 |

| 3. Mouth inside diameter | Position 2.0mm away from top or position 2.0mm away from top (a user speciality) | φ24.94 | ±0.08 |

| 4. Diameter across thread root | Diamer across thread root (at 0° position) | φ24.94 | ±0.08 |

| 5. Body outside diameter 2 | Distance between Bead and neck support | φ25.71 | ±0.08 |

| 6. Diameter across thread of a screw | First thread from top | φ24.94 | ±0.08 |

| 7. Bead outside diameter | Outside diameter | φ27.97 | ±0.08 |

| 8. Bead height | Distance from top to Kabura (0.8mm from the edge) |

14.10 | ±0.08 |

| 9. Neck support height | Distance from top to neck support (0.8mm from the edge) |

21.01 | ±0.08 |

* The measurement condition in the table are initial set values (at an angle at which the pet bottle & preform is first set).

Refer to the illustration above for this initial setting.