Bottle thickness measuring system equipment PA-2000

|

This measuring equipment is intended to rapidly measure the thickness of the walls of PET bottles.It has dependable safety and long life, employs high grade sensor technology, and supports safety, high performance and expansion. This is the first Japanese manufactured plastic bottle thickness measuring instrument. It was developed using our infrared technology fostered over many years. We also guarantee the high reliability of this instrument when it is used to acquire fine measurement data during research and development of new products. This instrument permits measurement of a greater variety of plastic materials than ever before. |

|---|

Features

- Measurement of a wide variety of materials

- Applicable bottle materials include PE, PEN, PVC, PET, PP, PS and PC.

- Long-term stability of data

- The light source uses a black body, and the sensor unit employs a highly sophisticated thermostatic chamber.

- Visual confirmation of measurement position

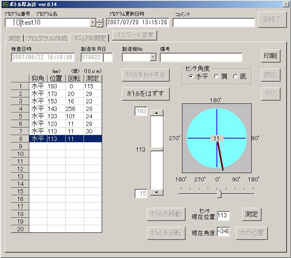

- A beam of visible laser light which has no adverse effect on the eyes is applied continuously as a spot to the measurement position.

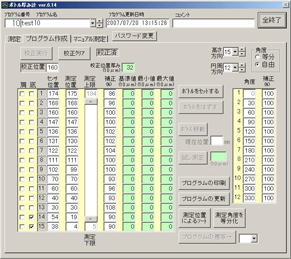

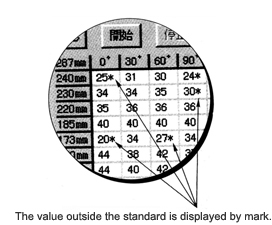

You can specify the measurement height and angle in steps of 1 mm and 1 degree, respectively, while visually checking the measurement position. - Replete software contents

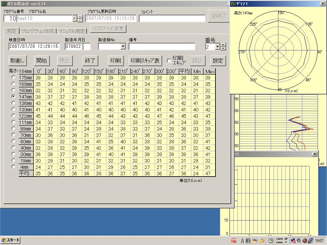

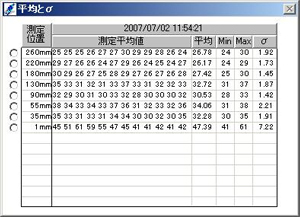

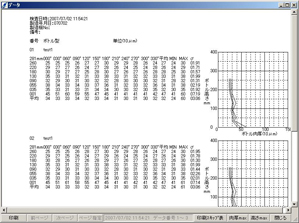

- Manual measurement, tabulation, measurement of each lot, standard deviation, non-standard value software, etc.

- Corner measurement

- This instrument can automatically measure the curved parts of the shoulder and bottom of a bottle by raising and lowering the sensor and also varying the sensor angle through 45 degrees.

- Easy Operation

- Allows continuous measurement and data collection of 100 bottles of one button.

- Data Processing

- Because the data are processed in text, it can be processed with Excel etc.

Structure

| Standard Components | Main unit (Measuring hardware), Computer, Printer, Measurement Software, Aggregation Software, Install CD-R, Safe/Dust proofing Cover, Emergency Stop Switch, Instruction Manual |

|---|---|

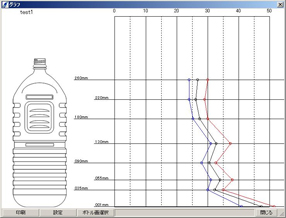

| Options | Bottle Graphics Software |

Spec

| Item | Content |

|---|---|

| Measuring Range | 0.1~1.5mm |

| Repeatability | ±10μm |

| Accuracy | ±2% of full scale It differs according to the quality, shape, and the color kind of bottle |

| RepeatabiIity | ≦±10μm(0.1~1.5mm thickness) |

| Measuring position | Side, shoulder and bottom The direction of height :3-15points(Set at 1mm each) The direction of the circumference : 1-12 points(Set every one degree) The measurement point is 180 point max. |

| Range of measurement | Height:max400mm Outside diameter:max200mm Inside diameter:min14mm |

| Measuring time | 30~45sec (Depends on the number of measuring points) |

| Measuring spot | φ3~5mm |

| Measuring result | Printer and CRT(LCD) |

| Computer | Desk top and note type computer (Windows XP) 256MB |

| Printer | A4 size |

| Interface | RS-232C |

| Line / Voltage | Selectable 100/120/220/240V 50/60Hz |

| VSize and weight | W300×H1170×D500mm 50Kg(max) |

Screen sample※Click for large image